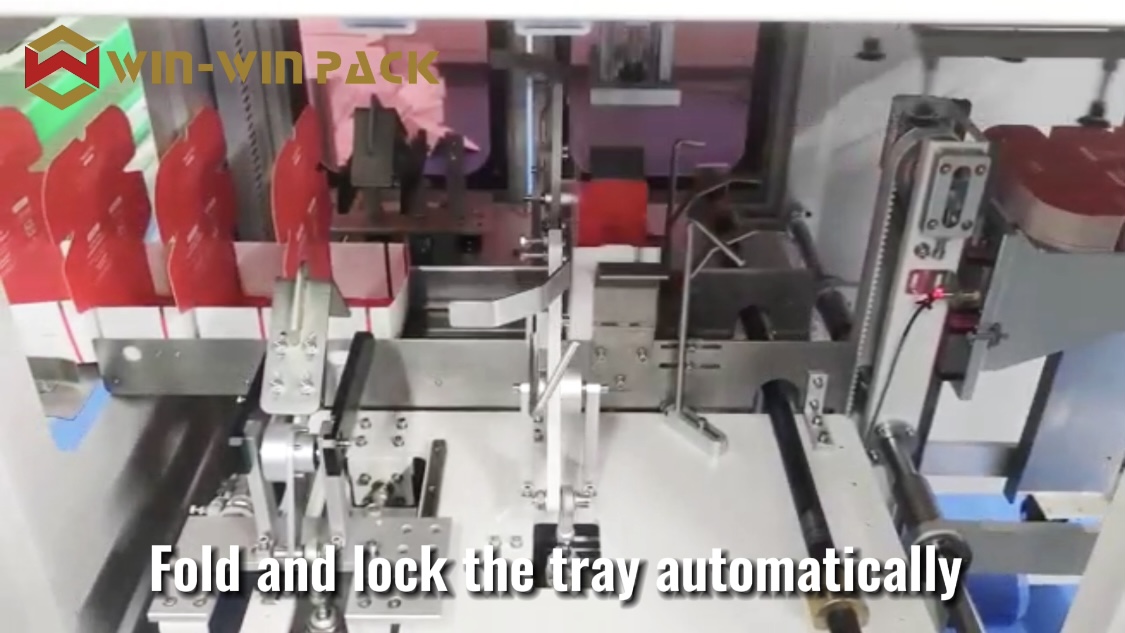

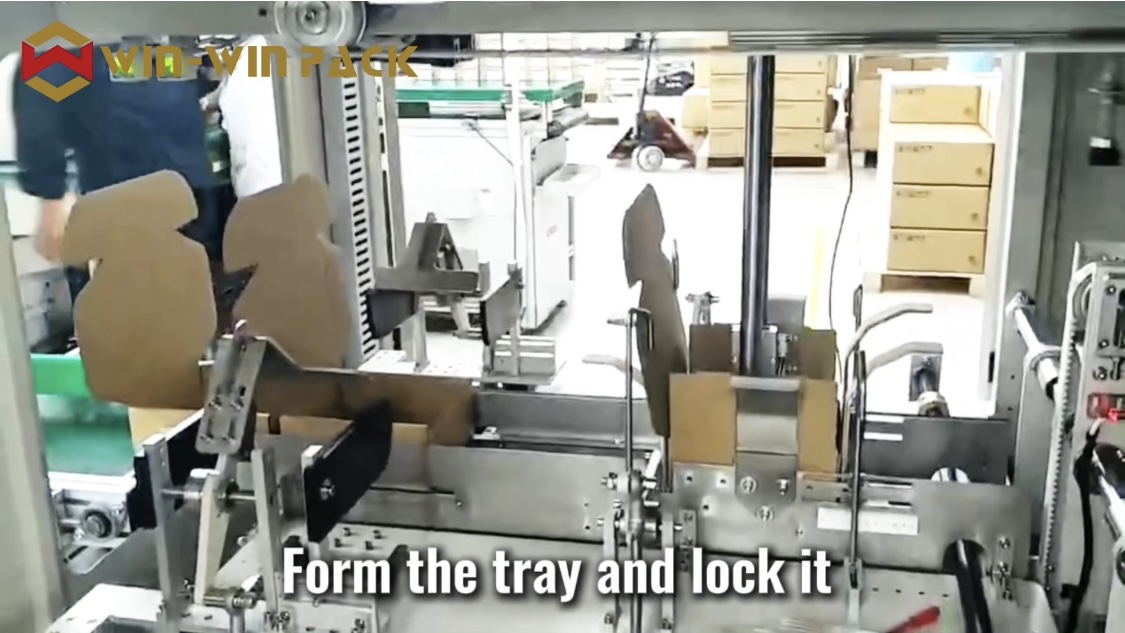

This video demonstrates the capabilities of a self-lock tray forming machine designed for e-commerce packaging. The machine automates the entire process, from forming cardboard trays to locking boxes, using servo motors to ensure precise and stable operation. It simplifies packaging tasks and enhances efficiency in product handling and shipping.

The labeling machine can be referred to as a "dual-axis label applicator" or a "side and top labeling machine". This equipment can perform labeling operations at two different positions (the left side and the top of carton) at the same mechanical location. Its feature is to achieve precise labeling at different positions through the movement of a swing arm.

Wrap Around Case Packer is a specialized machine used for automatic packaging of products, particularly in industries like food, beverages, pharmaceuticals, and personal care.

Designed by WIN-WIN PACK, the Tray Former machine is tailored for the rapid and precise placement of products onto trays. Leveraging advanced technology, this machine can adjust and customize tray shapes and sizes according to production requirements, catering to a wide range of industries, from food and beverages to electronics and medical devices.

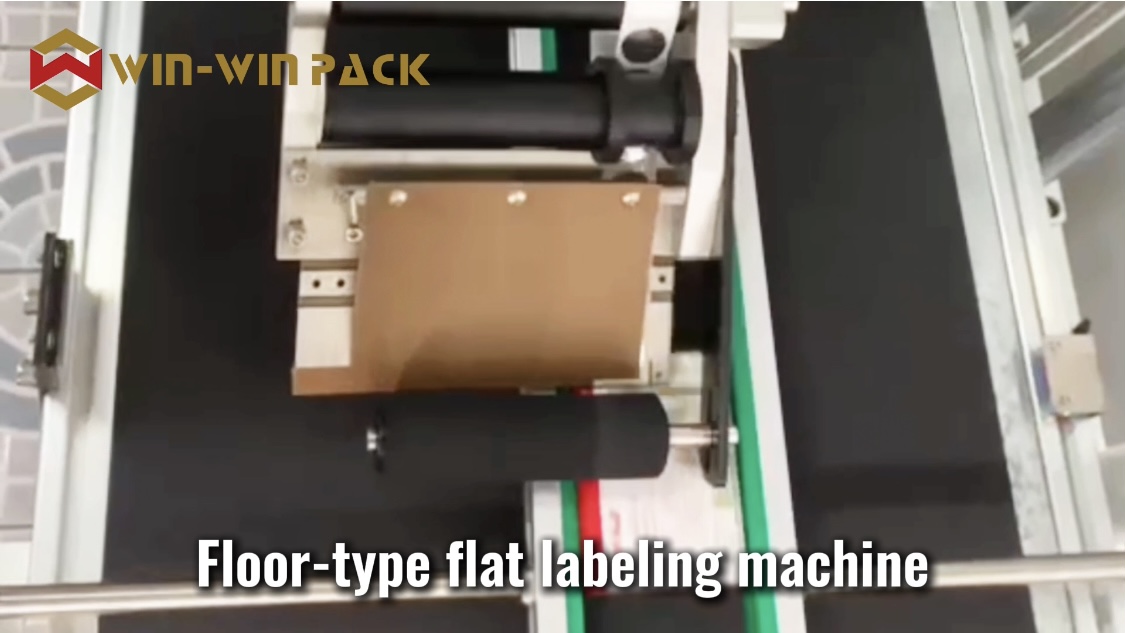

The Floor-Type Flat Labeling Machine is a state-of-the-art solution specifically designed for applying round labels to pharmaceutical products. This robust and efficient machine ensures precise labeling, essential for maintaining compliance and quality in the pharmaceutical industry.

This automatic floor-type flat labeling machine is designed for applying circular or various shaped labels on regular products in industries such as food, medicine, electronics, daily chemicals, and stationery. It offers efficient labeling solutions with easy operation and wide application versatility.

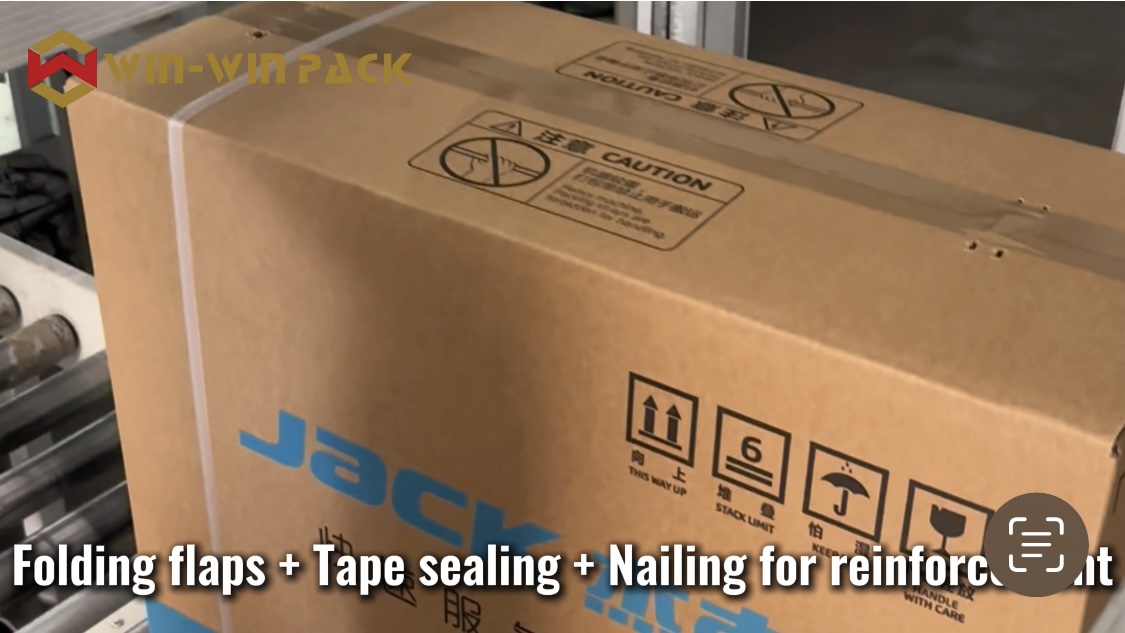

The WIN-WIN PACK Carton Sealer combines folding flaps, tape sealing, and nailing to provide a highly efficient and secure packaging solution. With six years of proven reliability, this versatile sealer is designed to handle high-volume operations, reduce labor costs, and ensure the safety and integrity of your packaged products.

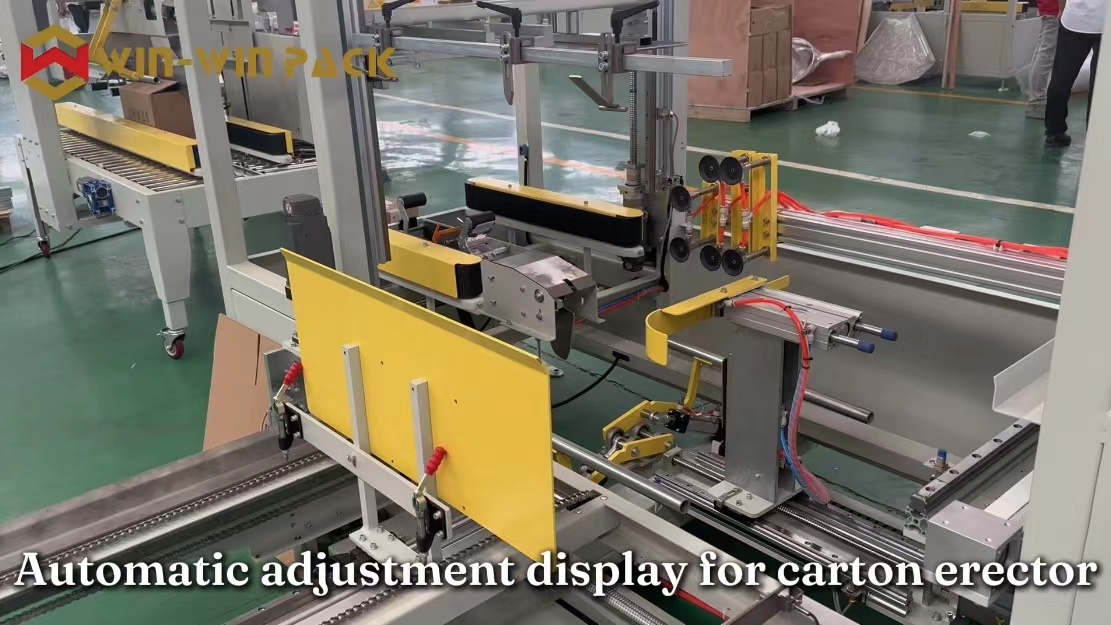

This video demonstrates the functionality of the automatic adjustment display for a carton erector, focusing on three key aspects.

The cartoning machine consists of various components, including a carton forming mechanism, product loading system, and sealing unit. The carton forming mechanism shapes flat carton blanks into three-dimensional boxes, creating a sturdy packaging structure. The product loading system then places pharmaceutical items into the formed cartons, ensuring precision and speed in the packaging process. Finally, the sealing unit securely closes and seals the cartons, preparing them for distribution.

Floor-Type Flat Labeling Machine for Mushrooms/Labeling Machine/Label Applicartor