Carton Design Guide -- How Should Cartons Be Designed for Machines Like Carton Erector and Sealer?

2024-10-25

How Should Cartons Be Designed for Machines Like Carton Erector and Sealer?

Since machine operations are standardized, unlike the flexible movements in manual handling, meeting customer needs for low error rates and attractive sealing outcomes with machinery requires higher consistency in carton design. The following outlines how to create cartons optimized for machine use.

Regarding Fold Creases:

a. For cartons with five or more layers, deep creases are necessary.

b. For five-layer or thicker cartons, the creases on the side long flaps should ideally be positioned one carton thickness above those on the front and back short flaps.

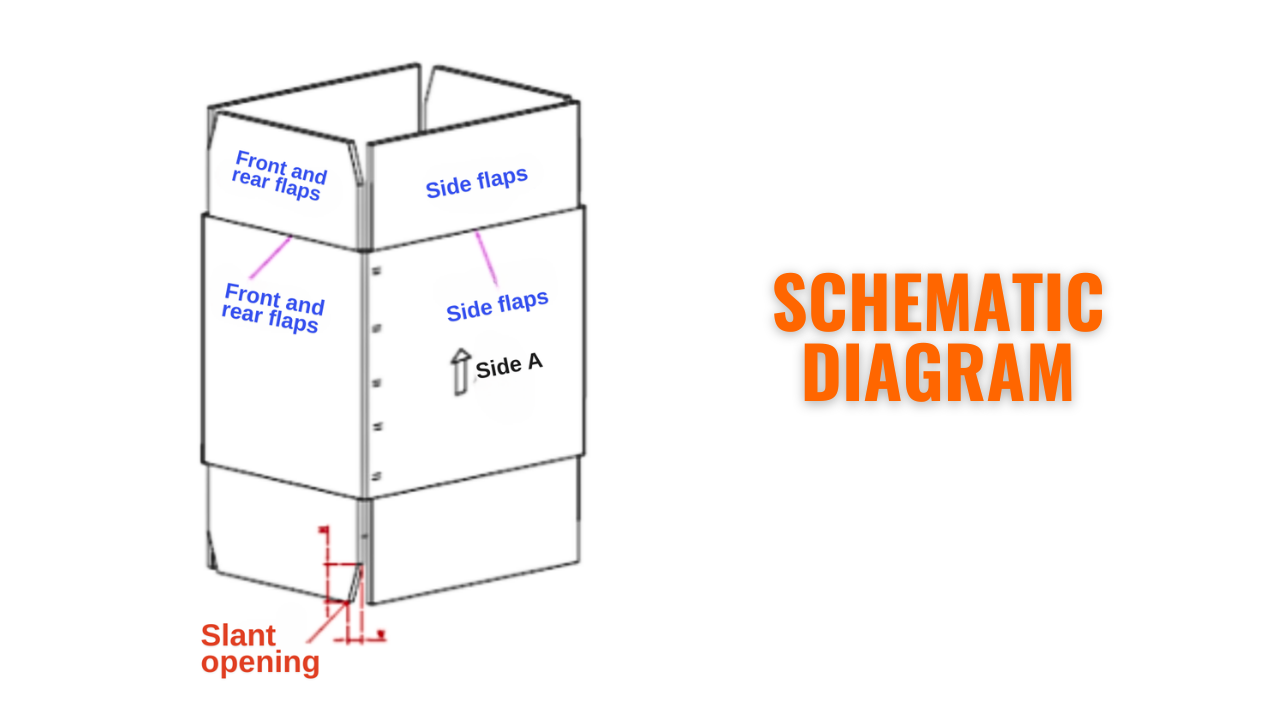

About the A-Side:

a. The A-side refers to the face that the suction cups of the carton erector engage.

b. The print orientation on the A-side defines the carton’s top and bottom.

c. The print orientation on the A-side also determines the machine’s forming direction (either to the left or the right).

d. A single machine requires a consistent A-side print orientation for all cartons.

e. Before forming, ensure the A-side has no fold marks and that its surface is flat.

Regarding Material:

a. The material should not be overly soft and must have a smooth surface—this is particularly important for high-speed carton erectors. When possible, provide samples.

b. For materials thicker than five layers, samples should be provided for confirmation.

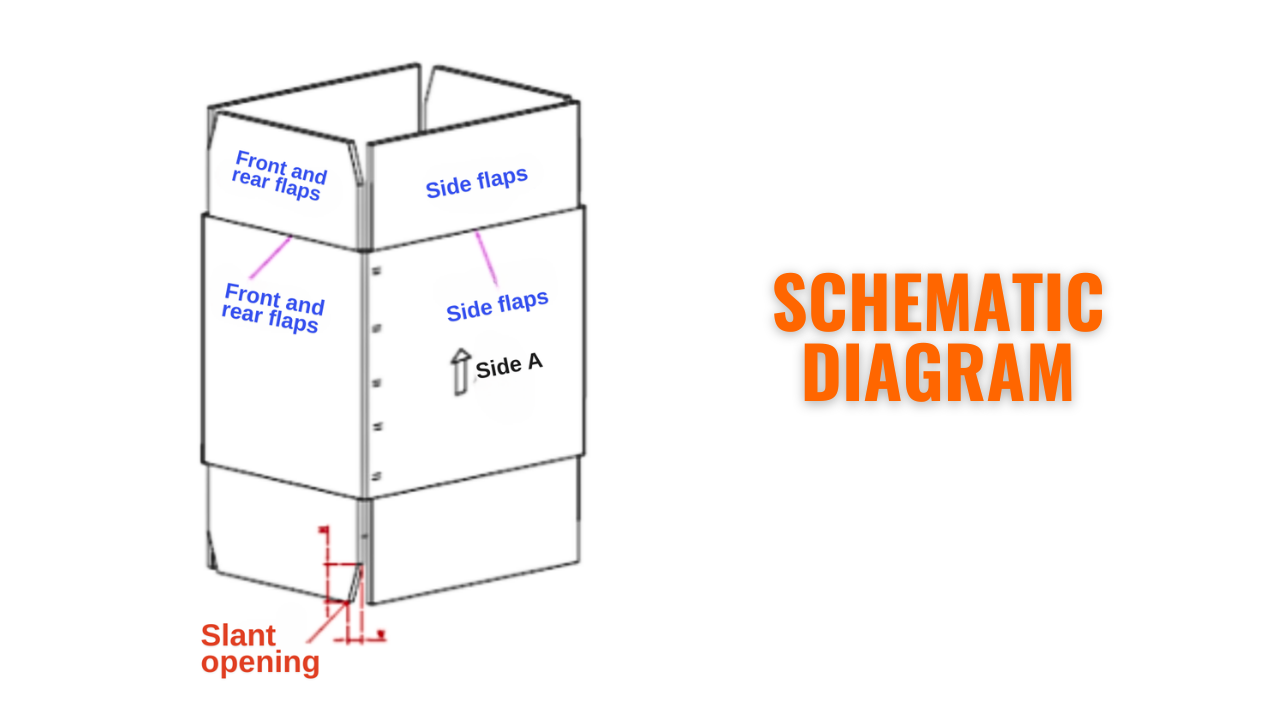

About Slanted Cuts:

a. Ideally, all inner flaps of carton materials should have slanted cuts, particularly for cartons with five or more layers or those that require high-speed handling.

b. The purpose of the slanted cuts is to prevent jamming caused by structural inconsistencies in stapled or glued cartons.

c. As illustrated, the dimensions of slanted cuts should be: H approximately 1/3 of the inner flap height, W approximately four times the carton thickness.

About Flaps:

a. When manually folded flat, the two side outer flaps should not overlap; ensure a 1-2mm gap.

b. When the front and back inner flaps are folded flat, they should also not overlap. If overlap occurs, provide samples for verification.

c. For square cartons, the front, back, and side outer flaps should be the same size, and slanted cuts are recommended for smooth forming.

About Dimensions:

a. For carton erector planning, it is advisable to provide a full list of specifications (length, width, height) for reference.

b. Take special care with square cartons where length, width, and height differ significantly.

c. Carton erectors typically operate such that if they work well with larger cartons, they may not handle smaller ones as effectively, and vice versa. Cartons with vastly different proportions may not suit the same mechanisms.