Carton Erector -- Why Are Vertical Robot Arm Servo Carton Erectors Like the WWP-S400 and WWP-S500 a

2024-09-23

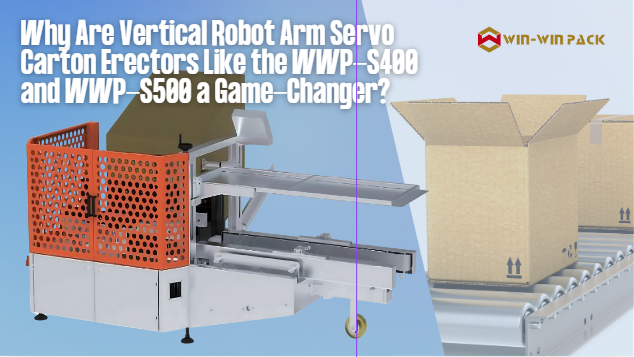

Why Are Vertical Robot Arm Servo Carton Erectors Like the WWP-S400 and WWP-S500 a Game-Changer?

What makes the WWP-S400 and WWP-S500 models so important for industries like logistics, retail, and manufacturing? These advanced carton erectors combine precision and efficiency with user-friendly features, making them an excellent choice for businesses seeking reliable packaging solutions.

How do these machines ensure accuracy? Both models incorporate a dual servo motor system, which synchronizes the movement of belts on either side of the carton. This precision guarantees that the carton remains square and intact during the forming process—vital for maintaining product integrity throughout the supply chain.

What about ease of use? One of the standout features of the WWP-S400 and WWP-S500 is their open design, which provides operators with full visibility of the process. This allows for quicker adjustments, easier access, and overall better control of the operation. Low-noise functioning and smooth carton handling ensure that the product quality remains intact, with minimal risk of damage to the packaging materials.

What are the differences between the two models? For businesses needing greater capacity, the WWP-S500 offers enhanced capabilities, including the ability to handle larger carton sizes and operate at higher speeds. This makes it a great choice for industries managing larger production volumes, offering flexibility for different carton dimensions.

Both models are designed for seamless integration into existing production lines, allowing for continuous operation with minimal stops. Their user-friendly design and automated features make them well-suited for companies that prioritize efficiency and quality. Whether your business handles small-scale or large-scale production, these carton erectors are equipped to meet the demands of modern packaging needs.