The Importance of Checkweighers in Carton Packaging Lines

2024-05-20

In the modern packaging industry, carton packaging lines have become an indispensable part of automated production. Among the key equipment on this automated production line, the checkweigher plays a crucial role. This article will explore the function and importance of checkweighers in carton packaging lines.

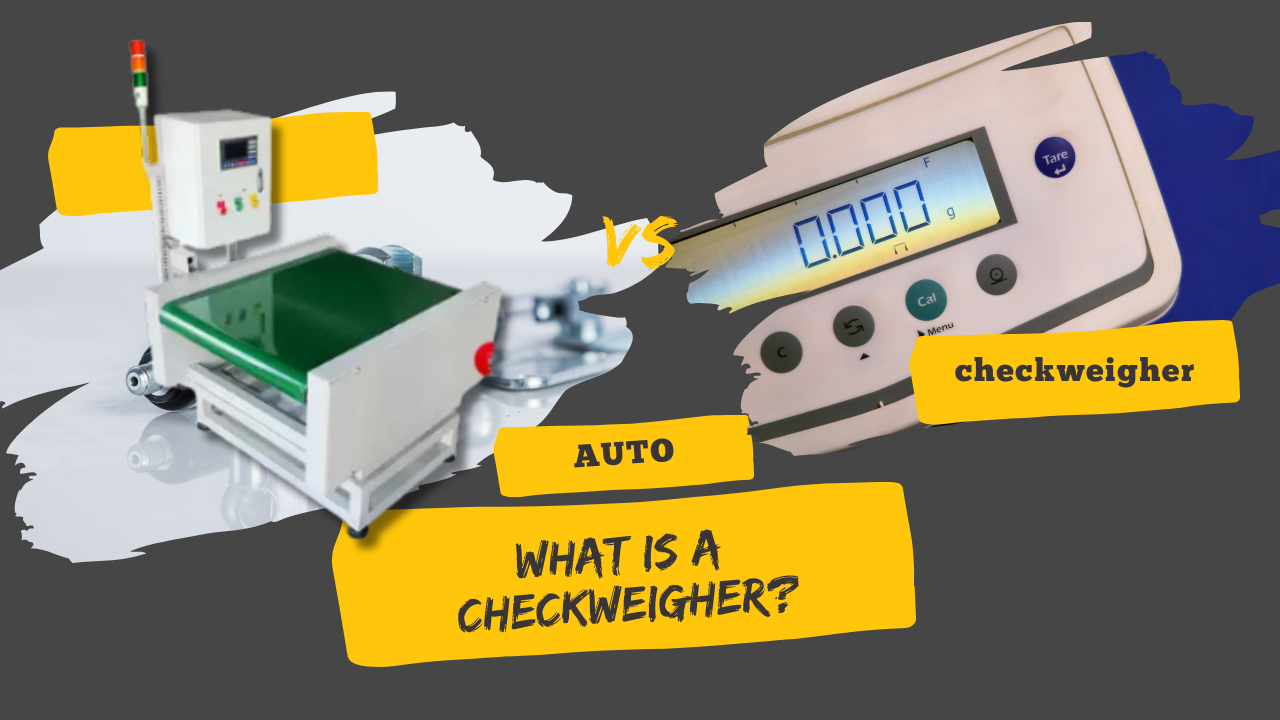

What is a Checkweigher?

A checkweigher is a device used to detect and weigh products. Typically installed at a certain point in the packaging production line, it accurately weighs each package to ensure it meets the predetermined standards. If a package's weight is outside the set range, the checkweigher will alert the system or automatically reject the non-compliant product, thus ensuring the quality and consistency of each product.

Specific Roles of Checkweighers in Carton Packaging Lines

1. Quality Control

The role of checkweighers in quality control is particularly significant. By monitoring the weight of each carton in real-time, checkweighers can effectively identify underfilled or overweight issues during the packaging process. This prevents substandard products from reaching the market, reduces customer complaints, and enhances the company's reputation.

2. Increasing Production Efficiency

Traditional manual weighing methods are time-consuming and labor-intensive, and they are prone to human error. The automated operation of checkweighers greatly increases production efficiency. They can quickly and accurately check the weight of each carton, ensuring the production line operates at high speed and accuracy, thereby improving overall production efficiency.

3. Cost Savings

Through precise weight control, checkweighers help companies effectively reduce material waste. For instance, in food packaging, overfilling each package can result in significant cost waste over time. Checkweighers ensure that each package's weight is within the set range, thus saving production costs.

4. Regulatory Compliance

In many countries and regions, product packaging weight must comply with relevant regulations and standards. Checkweighers assist companies in ensuring that their products meet these regulatory requirements, avoiding legal disputes and fines due to overweight or underweight issues.

5. Data Recording and Analysis

Modern checkweighers are often equipped with data recording and analysis functions. By recording the weight data of each carton, companies can analyze the production process, identify potential production issues, and make improvements. Additionally, this data provides strong support for quality traceability.

Selecting and Maintaining Checkweighers

Choosing the right checkweigher is critical for companies. Consider the following points when selecting a checkweigher:

Accuracy and Speed: The accuracy and speed of the checkweigher must meet the requirements of the production line.

Durability and Stability: The equipment should have good durability and stability, capable of long-term stable operation.

Ease of Operation and Maintenance: The equipment should be easy to operate and maintain, reducing downtime.

During use, companies should regularly calibrate and maintain the checkweigher to ensure it remains in optimal working condition.

The role of checkweighers in carton packaging lines cannot be underestimated. They ensure product quality, increase production efficiency, save costs, assist companies in complying with relevant regulations, and facilitate data analysis and quality traceability. With continuous advancements in automation technology, the application of checkweighers in the packaging industry will become more widespread, becoming a crucial tool for companies to enhance their competitiveness.