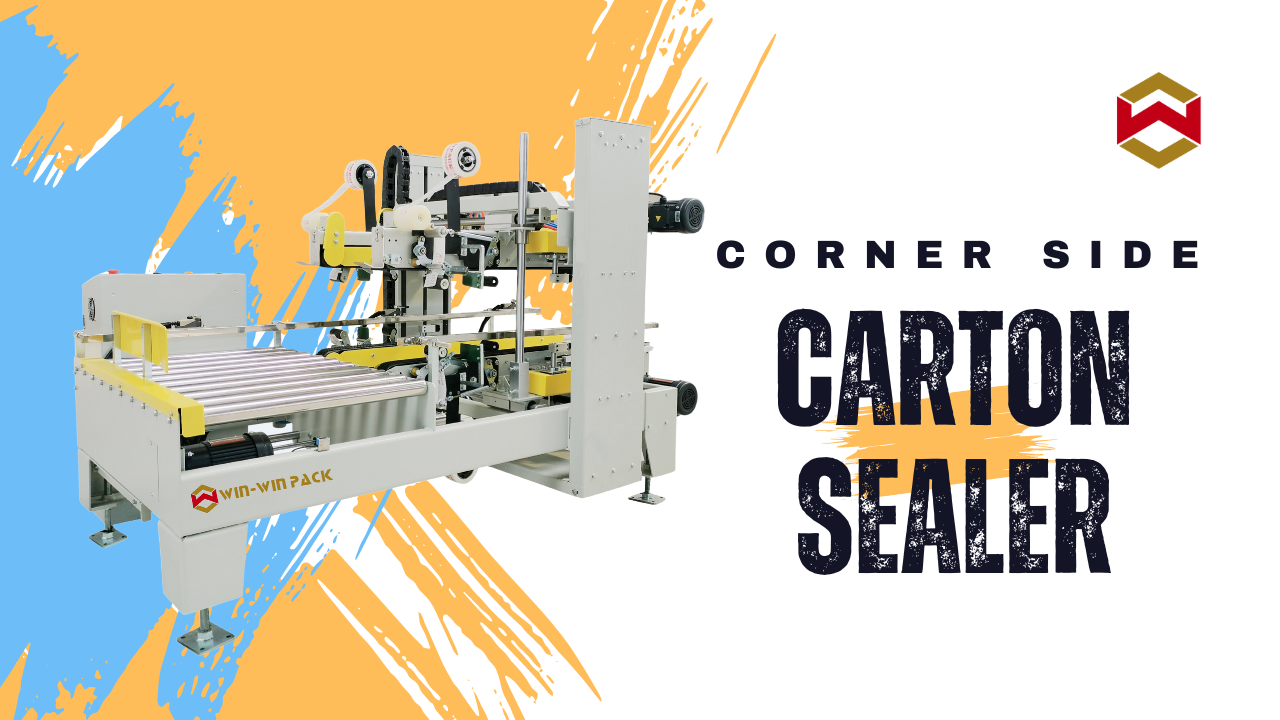

Advanced Carton Sealing Solutions: The WIN-WIN PACK Corner and Side Type Carton Sealer

2024-11-25

The corner and side type carton sealer from WIN-WIN PACK represents the culmination of extensive research and development. With its advanced features, reliable performance, and unique innovations, it is designed to meet the demanding needs of modern packaging operations. Whether for precise adjustment, maintenance-free operation, or enhanced belt performance, this machine stands out as a leading solution in the carton sealing industry.

Our design philosophy focuses on modular assembly, allowing for flexible configurations to meet diverse customer needs. Each component of this series has been meticulously engineered to address common issues in carton sealing, ensuring both aesthetic appeal and robust internal structure.

Key Features

1. Maintenance-Free Operation

Transmission System: The engine transmission utilizes screw tuning, eliminating the need for additional lubrication.

Frame Design: The main frame is precision-cut using high-density radium. The width and height adjustment mechanisms and the main engine header are designed for continuous, smooth operation. The sliding components feature linear bearings pre-lubricated, thus requiring no extra lubrication.

2. Innovative Belt Support

U-Shaped Cingulated Groove: This unique design supports the belt terminal, preventing drooping and ensuring stable operation.

3. Precise Adjustment:

Synchronous Adjustment Mechanism: The adjustable four-corner sealer employs a toothed synchronous adjustment system for the width, height, and size of the cartons. This ensures smooth, shake-free movements and accurate central positioning.

4. Unique Functional Characteristics:

Synchronous Gear Bars: The special translation structure is based on the principle of synchronous movement of right and left gear bars.

Unilateral Belt Design: The main engine header incorporates a unilateral belt system with a U-model path and half-arc zenith, preventing tape breakage and ensuring the belt works effectively even when the adhesive tape is difficult to apply.

Four-Corner Belt Engine: Each corner operates with unilateral belts, facilitating easy loading and transport.

5. Proven Reliability:

Years of Improvement: This series has undergone nine years of design refinements, resulting in a mature, reliable machine with minimal problems and low fault rates, making maintenance straightforward.

6. Enhanced Belt Performance:

Corner-Type Pasting Method: Recognizing the challenges with different adhesive tape thicknesses, the machine employs a unique pasting method. Unlike other flat pasting methods, this machine uses flat forwarding pasting at the four corners’ width.

Innovative Belt Design: After extensive testing and various pasting methods (such as round-hair and slight huffing pasting tapes), the design settled on using durable nylon thread for the pasting belt. Although some minor fluttering persists due to the softness of the adhesive tape, this remains an industry-wide issue. Our design, however, offers advanced performance compared to other machines.