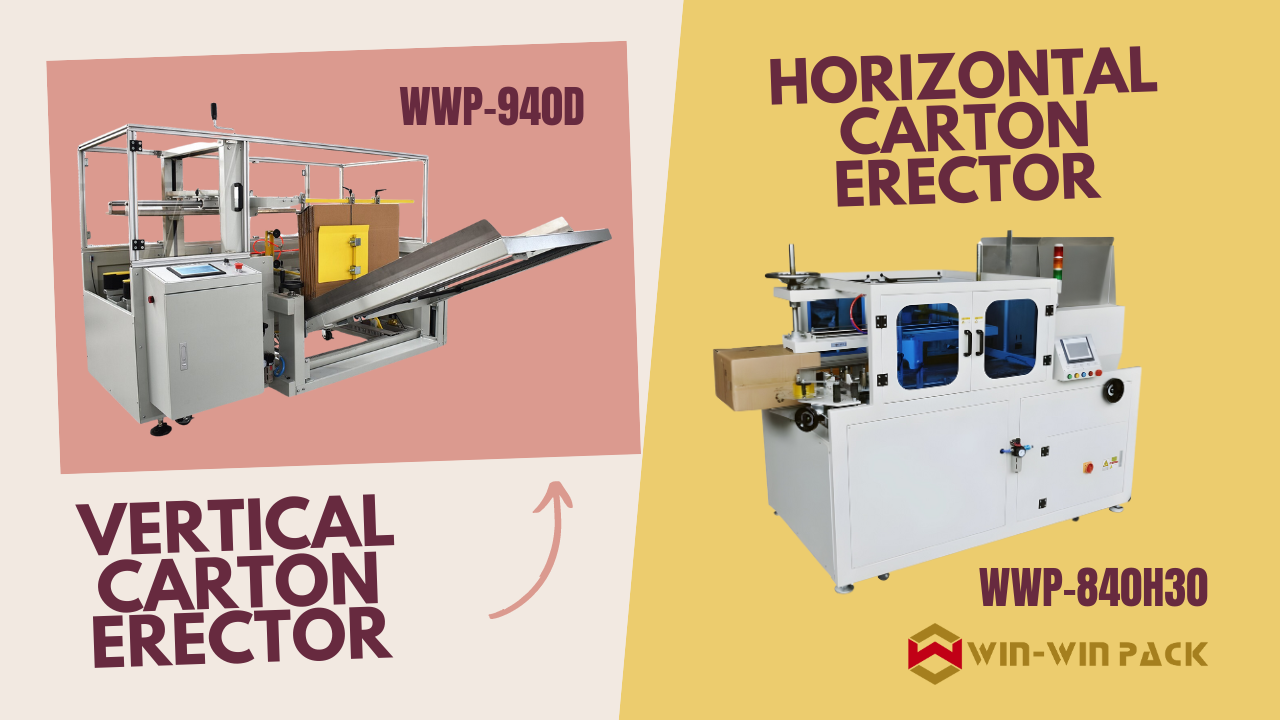

The difference for Horizontal carton erector and Vertical carton erector

2024-02-24

Understanding the Difference Between Horizontal and Vertical Carton Erectors

In the realm of packaging machinery, the choice between horizontal and vertical carton erectors can significantly impact efficiency, speed, and the overall packaging process.

A. Horizontal Carton Erector: WWP-840H30/WWP-840H50

Running System:

Controlled by Cam: Operates with mechanized precision, ensuring accurate and stable performance.

Carton Placement: Cartons are placed horizontally, minimizing the risk of carton fall during the erecting process.

Packaging Speed: Offers higher speeds of 20-25 cartons per minute, making it suitable for rapid production lines.

Carton Compatibility: Ideal for square cartons, with a design optimized for horizontal movement and secure packaging.

Machine for Packing Soft/Small/Thin Cartons:

Cartons are handled horizontally, reducing the risk of damage during the erecting process.

Utilizes suction cup technology for gentle handling, ensuring cartons remain intact throughout the packaging process.

Machine Speed for Standard Operation:

Can achieve speeds of 30 or 50 cartons per minute, depending on the specific model and configuration.

Carton Sending: Does not require belts for carton transport, simplifying the machinery setup.

B. Vertical Carton Erector: WWP-940D/WWP-940D15

Running System:

Controlled by PLC: Utilizes programmable logic controllers for action sequencing, resulting in controlled but slower operation.

Carton Placement: Cartons are placed vertically, potentially leading to carton instability during the erecting process.

Packaging Speed: Operates at slower speeds, typically around 10-15 cartons per minute, suitable for applications where speed is not a primary concern.

Carton Compatibility: Can handle square cartons but may experience slower operation due to the vertical arrangement.

Machine for Packing Soft/Small/Thin Cartons:

Vertical orientation of cartons may lead to increased risk of carton damage or misalignment during erecting.

The use of belts for carton transport may result in carton breakage or improper sealing if not controlled meticulously.

Machine Speed for Standard Operation:

Operates at lower speeds compared to horizontal carton erectors, making it suitable for applications prioritizing cost-effectiveness over speed.

Carton Sending: Utilizes belts controlled by motors for carton transport, adding complexity to the machinery setup.

Horizontal and vertical carton erectors offer distinct advantages and drawbacks depending on specific packaging requirements and production priorities. While horizontal machines excel in speed, precision, and compatibility with square cartons, vertical machines may be suitable for applications prioritizing cost-effectiveness and lower speed requirements. Understanding these differences is essential for selecting the right carton erector to optimize your packaging process effectively.