Application in Packaging Machines: Packaging Line - Mechanical Structure

2025-02-18

Application in Packaging Machines: Packaging Line - Mechanical Structure

In the realm of packaging machines, the packaging line stands as a cornerstone of industrial operations, orchestrating the intricate ballet of product handling, containment, and delivery. Central to this system is its mechanical structure, a fundamental framework that dictates the efficiency, reliability, and adaptability of the entire production process.

Understanding the Mechanical Structure

Packaging lines are characterized by their robust mechanical structures, comprising a sophisticated interplay of conveyors, robotic arms, and integrated systems designed to seamlessly integrate various stages of packaging. These components work in tandem to transport products, apply packaging materials, seal containers, and prepare goods for distribution.

Key Components and Functions

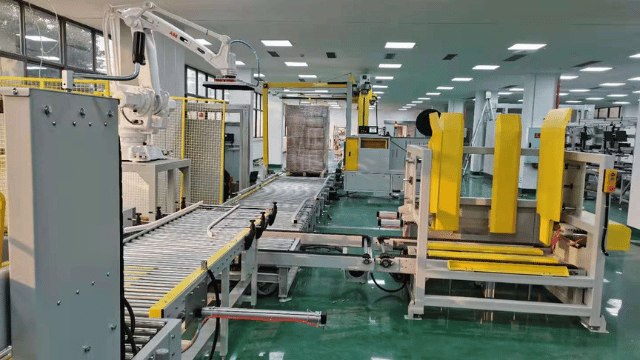

Conveyors: Vital arteries of the packaging line, conveyors move products from one station to the next with precision and reliability. They come in various types—belt conveyors for smooth surfaces, chain conveyors for heavy loads, and roller conveyors for controlled movement.

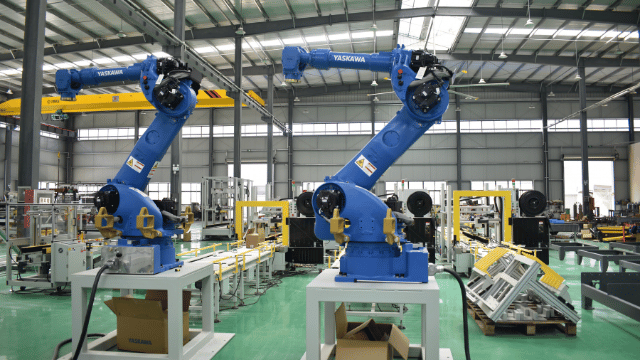

Robotic Arms: Serving as the agile workforce of the packaging line, robotic arms execute tasks requiring dexterity and speed. They handle tasks such as picking and placing products, applying labels, and stacking items in boxes or pallets.

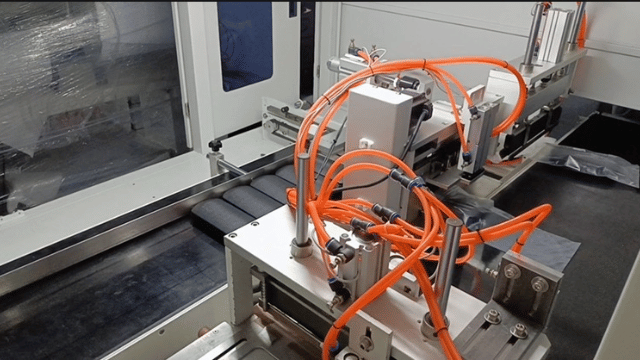

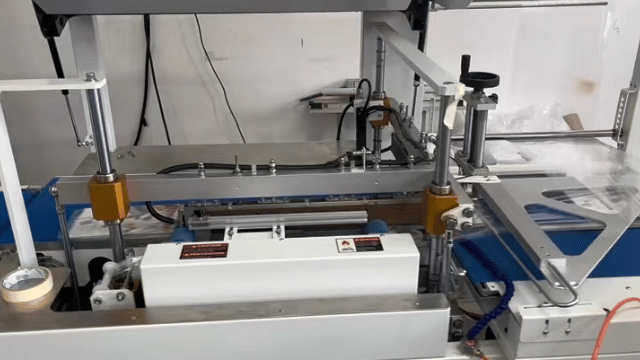

Packaging Stations: These specialized workstations are equipped with machinery for specific packaging tasks, including sealing, labeling, wrapping, and coding. Each station is optimized for efficiency and accuracy, ensuring products are prepared according to stringent quality standards.

Advantages of Mechanical Structures

The mechanical design of packaging lines offers several advantages:

Reliability: Mechanical systems are robust and proven, providing consistent performance under demanding production conditions.

Flexibility: Despite their structured nature, modern mechanical systems can be adapted and configured to accommodate various product types, sizes, and packaging formats.

Cost-Effectiveness: Initial investment costs for mechanical systems are often lower compared to highly automated alternatives, making them accessible for a wide range of production scales and budgets.

Challenges and Optimization

While mechanical structures excel in reliability and initial affordability, they face challenges in handling complex product geometries and maintaining high-speed operations without compromising precision. Optimization efforts focus on fine-tuning conveyor speeds, optimizing workflow layouts, and integrating advanced sensors and controls to enhance overall system efficiency and reduce downtime.

Future Directions

Looking forward, advancements in robotics, artificial intelligence, and machine learning promise to further revolutionize packaging line operations. Integration of smart technologies will enable packaging lines to autonomously adapt to changing production demands, enhance predictive maintenance capabilities, and elevate overall production efficiency to unprecedented levels.

In conclusion, the mechanical structure of packaging lines underscores their foundational role in modern industrial packaging. By continually refining these systems and embracing technological advancements, manufacturers can ensure their packaging operations remain at the forefront of efficiency, reliability, and innovation.