Advantages of palletizing robots in hazardous goods handling: improving safety and efficiency

2024-05-27

Advantages of palletizing robots in hazardous goods handling: improving safety and efficiency

Advantages of palletizing robots in hazardous goods handling

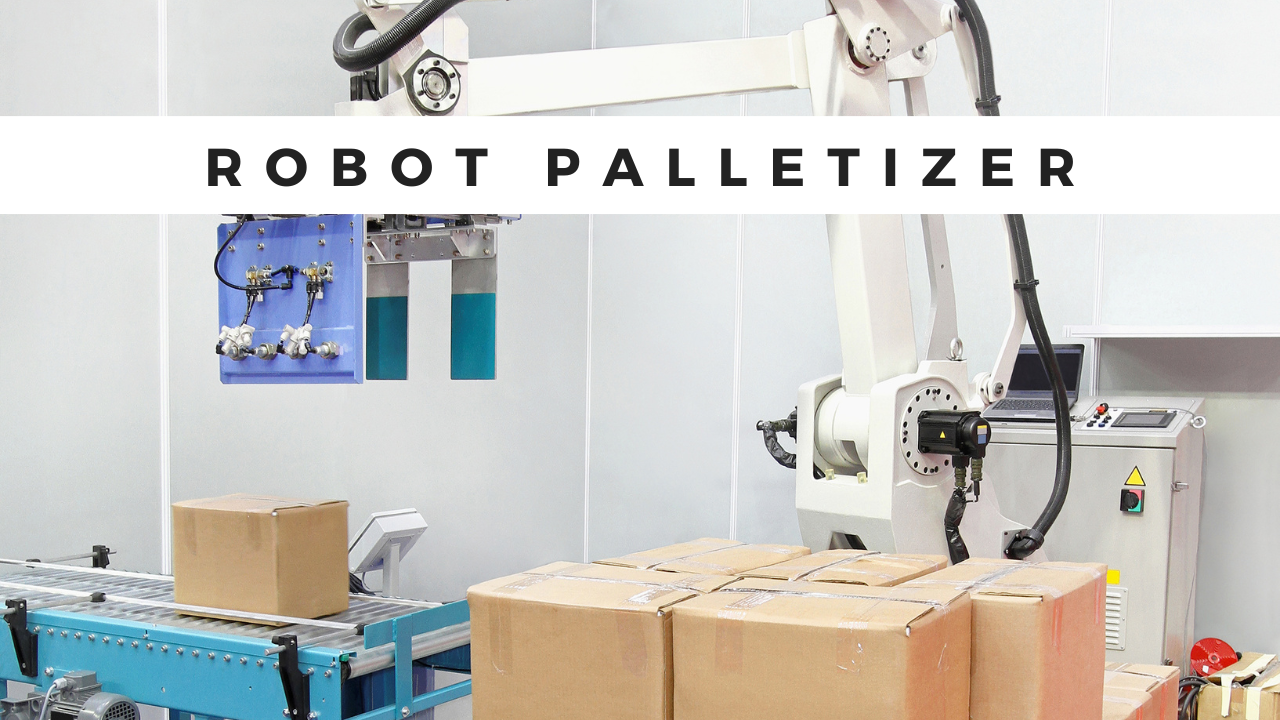

In modern industry, handling hazardous materials such as chemicals and pharmaceuticals is an extremely challenging task. Manual operation not only presents safety hazards, but can also lead to inefficiency and product damage. The palletizing robot system provided by WIN-WIN PACK significantly improves the safety and efficiency of dangerous goods handling through automation technology, providing reliable solutions for various industries.

Improve safety: reduce manual operation risks

When handling hazardous materials, workers' risk of exposure to hazardous materials and hazardous environments increases significantly. The traditional manual palletizing method is not only labor-intensive but also prone to accidents. WIN-WIN PACK's palletizing robot system can completely replace manual operations and free workers from dangerous environments.

These robots are equipped with advanced sensors and control systems that can accurately detect and handle various dangerous goods, ensuring the safety of every operation step. For example, when handling chemicals, robots can avoid contact with hazardous substances and safely stack chemicals into designated locations through precise mechanical operations, reducing the risk of leakage and contamination.

Efficiency: Optimize processing flow

WIN-WIN PACK's palletizing robot not only improves safety, but also greatly improves processing efficiency. Whether full-level stacking or stacking of individual boxes, bags, barrels or drums, these robots complete the task with high speed and precision. Its fast and stable automation solution makes the dangerous goods handling process smoother and more efficient.

In addition, the palletizing robot can work continuously without being affected by manual fatigue, ensuring the continuity and stability of production. This is particularly important for industries such as pharmaceuticals that handle high-frequency and high-precision operations. By reducing manual intervention, production line uptime is maximized and overall operating costs are reduced.

Diverse solutions: meet different needs

WIN-WIN PACK's palletizing robot system provides a variety of size, load capacity and operating speed options, which can flexibly adapt to different types and specifications of dangerous goods handling needs. Whether it's lightweight pharmaceutical packaging or heavy chemical drums, these robots can do the job. Its high degree of customizability allows each solution to be optimized according to specific application scenarios to ensure the best processing results.

For example, in the pharmaceutical industry, precision and sterility are critical. WIN-WIN PACK's robot can complete palletizing tasks with extremely high precision, avoiding any possible contamination and damage, and ensuring the safety and effectiveness of pharmaceuticals. In the chemical industry, when handling chemical containers with heavy weight and complex shapes, palletizing robots can easily cope with various challenges with their strong load capacity and flexibility.

Future Outlook: Continuous Innovation and Development

With the continuous advancement of industrial automation technology, the application prospects of palletizing robots in dangerous goods handling are becoming increasingly broad. WIN-WIN PACK will continue to be committed to technological innovation, improve the intelligence and adaptability of robot systems, and provide customers with more advanced and efficient solutions.

By introducing artificial intelligence and machine learning technology, future palletizing robots will have stronger autonomous decision-making capabilities and environmental adaptability, be able to handle various complex tasks more accurately, and further improve the safety and efficiency of dangerous goods handling. At the same time, as robots become more popular and costs decrease, more companies will have the opportunity to deploy this advanced technology to achieve comprehensive production automation and safety.

WIN-WIN PACK's palletizing robot system has demonstrated significant advantages when handling dangerous goods such as chemicals and pharmaceuticals. It helps companies achieve higher operational efficiency by improving safety, optimizing efficiency and providing diversified solutions. . As technology continues to develop, these robots will play a key role in more industries, bringing more possibilities to industrial automation and safe production. WIN-WIN PACK will continue to lead the development in this field and provide customers with the highest quality automated palletizing solutions.