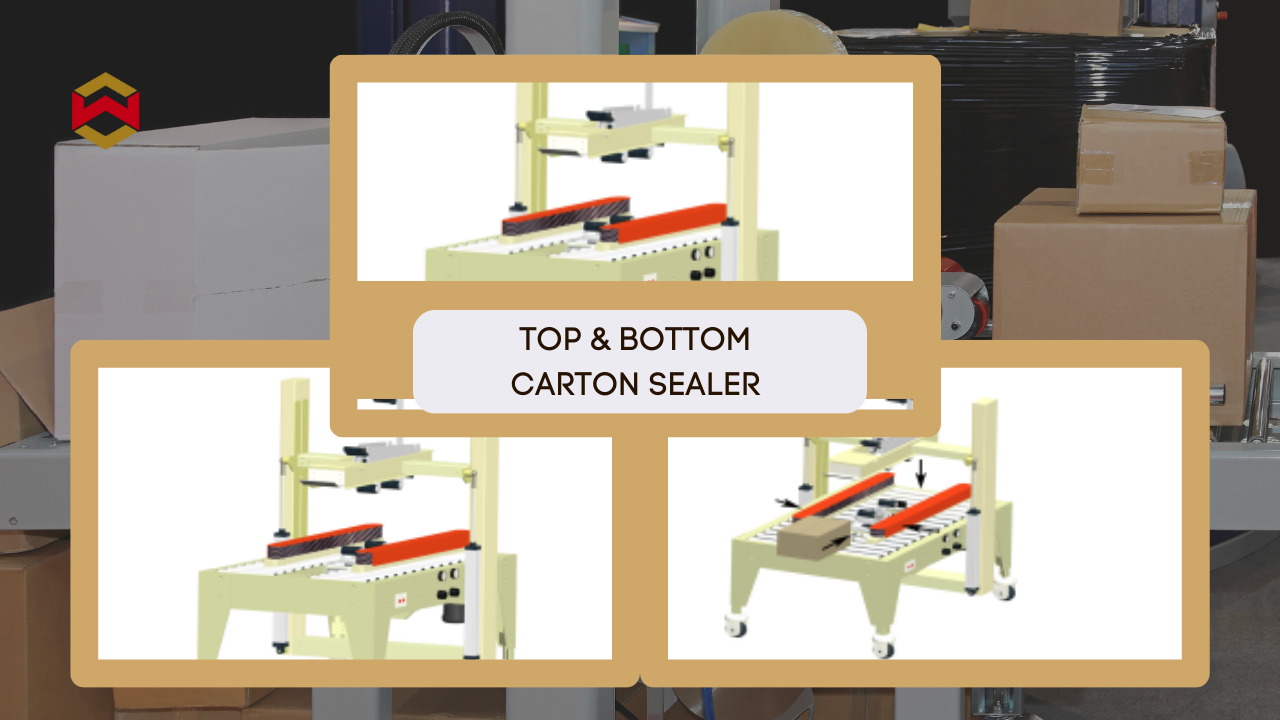

Top and Bottom Carton Sealer Machine Structure and Adjustment Instructions

2024-12-18

Top and Bottom Carton Sealer Machine Structure and Adjustment Instructions

The top and bottom carton sealer is a robust and meticulously designed machine, incorporating various components that work in unison to achieve seamless operation. The structure of the machine typically includes a frame, conveyor system, sealing mechanisms for both the top and bottom flaps of cartons, and control units for operation and adjustment.

Adjustment instructions are critical for ensuring the machine operates correctly with different carton sizes and types. These instructions guide operators through the process of setting up the machine for specific dimensions, ensuring the adhesive tape is applied accurately and the seals are secure. Adjustments may include the height and width settings to accommodate various carton sizes, the tension of the adhesive tape, and the speed of the conveyor system.

Operation Flow

The operation flow of a top and bottom carton sealer involves several key steps:

Loading: Cartons are manually or automatically fed into the machine.

Positioning: The cartons are positioned correctly within the machine using guides and sensors.

Sealing: The machine applies adhesive tape to the top and bottom flaps of the cartons as they pass through the sealing mechanisms.

Discharge: Sealed cartons are then conveyed out of the machine for further processing or shipment.

This automated flow enhances productivity by reducing the time and labor required for manual sealing, while also improving the consistency and reliability of the seals.

Adhesive Tape Installation and Adjustment

Installing and adjusting the adhesive tape is a crucial part of operating a carton sealer. Proper installation ensures that the tape adheres well and provides a secure seal. The process typically involves:

Mounting the Tape Roll: The adhesive tape roll is mounted on the designated holder within the machine.

Threading the Tape: The tape is threaded through the machine’s tape application path, ensuring it is correctly aligned with the sealing mechanism.

Adjusting Tension and Alignment: Operators adjust the tension to ensure the tape dispenses smoothly without tearing or misaligning. Proper alignment ensures the tape is applied straight and centered on the carton flaps.

Regular checks and adjustments are necessary to maintain optimal performance and to accommodate different types of adhesive tapes.

By understanding and mastering the key elements of machine structure, operation flow, and tape adjustment, operators and technicians can ensure the top and bottom carton sealer runs efficiently and reliably, enhancing the overall productivity and quality of the packaging line.