Labeling Machine -- Advancements in Labeling Technology: Traditional vs. Intelligent Labeling Machin

2024-06-15

Labeling Machine -- Advancements in Labeling Technology: Traditional vs. Intelligent Labeling Machine

Traditional Labeling Machines:

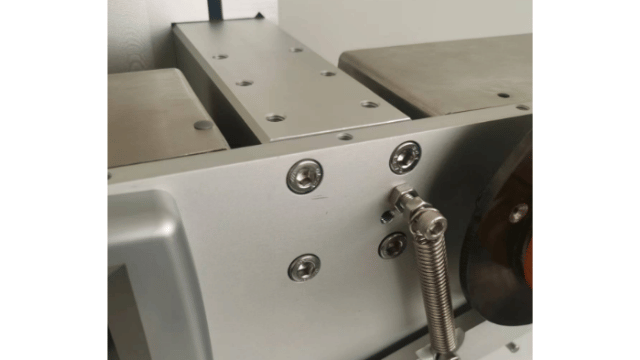

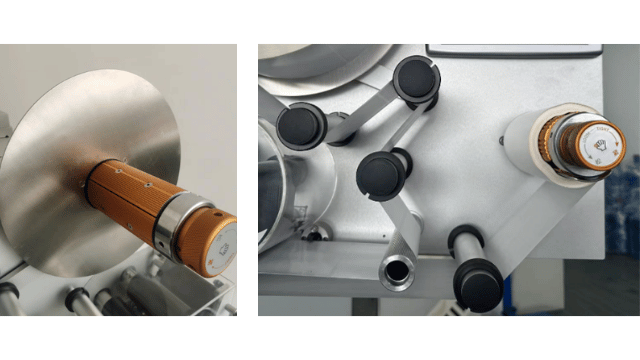

The roller can only run in one direction, and the label can only rewind up to 2cm after being dispensed. Therefore, a labeling arm needs to be installed to store labels, which are held by suction. This approach presents two issues: the use of an air source and the potential for labels to fall off during suction. The machine is equipped with a brake motor to control the label rewind; it can dispense labels but cannot rotate them back. This requires the use of a brake belt and similar consumable parts.

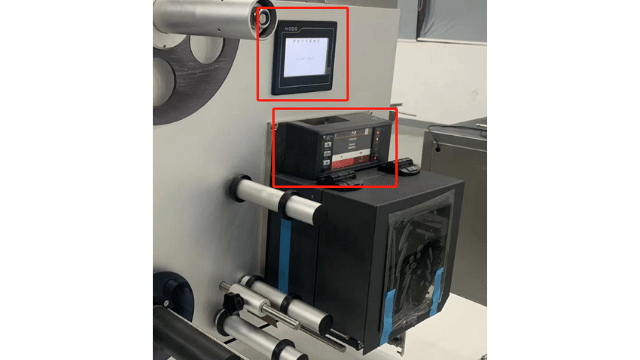

The machine has two touch screens, one for controlling the printer and the other for controlling the labeler, making operation complicated.

The machine has only one mode. To meet different requirements, many electrical components need to be added.

Intelligent Labeling Machines X8130/X8140:

Equipped with 5 motors, the entire machine is controlled by a CPU, allowing for label rewinding without the need for a brake motor, thus eliminating the need for brake belts and similar consumable parts. The labels can rewind the distance of one label, thereby eliminating the need for a labeling arm to buffer, as it is controlled by the CPU to balance label dispensing and rewinding.

The machine features a single touch screen to control the entire machine, making operation straightforward. Operators simply enter product and label information, select the labeling mode, and start labeling.

Features three modes:

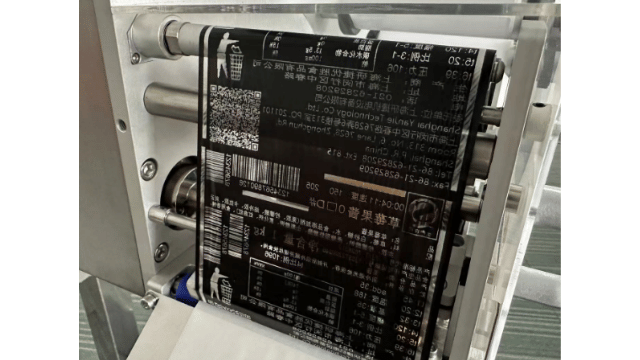

Print a label and affix it.

Print two labels and affix one.

High-speed labeling mode.

These modes enhance the machine's versatility and flexibility.

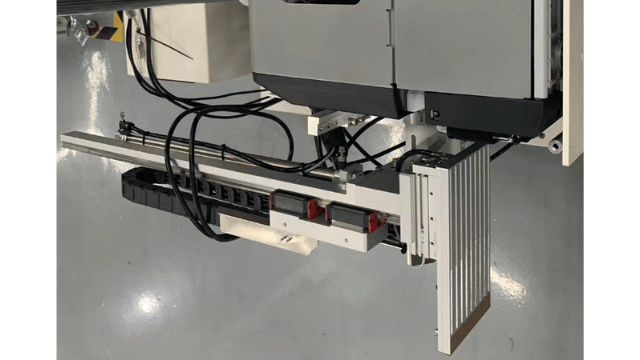

Due to the reduced number of electrical components and CPU-based control, the machine's size is significantly reduced.

Equipped with an Ethernet port for connecting multiple machines, such as scales and other equipment.

Precisely calculates the amount of ribbon needed for each label, which helps save on ribbon consumption.

It is easy to install. After the machine is packaged, it only has 2CBM. It is small in size and light in weight, so one machine can achieve another method. It can be side-sticked or changed to bottom-stick label or top-stick label, without the need to remake a new machine